NOT ANY SCREEN WILL DO

The right technology in the right place

It’s important to ensure the right technology is installed on a water intake.

Diversions with the wrong type of screen installed, or no screen at all, suffer problems like clogging and fail to protect fish.

Modern screens ease these issues, but need to meet criteria for native fish protection. The key is to lower the velocity of water entering a diversion, but not the volume.

This principle applies whether it’s a pump or a channel, deep water or shallow. By making the screen area larger, a much finer mesh can be used.

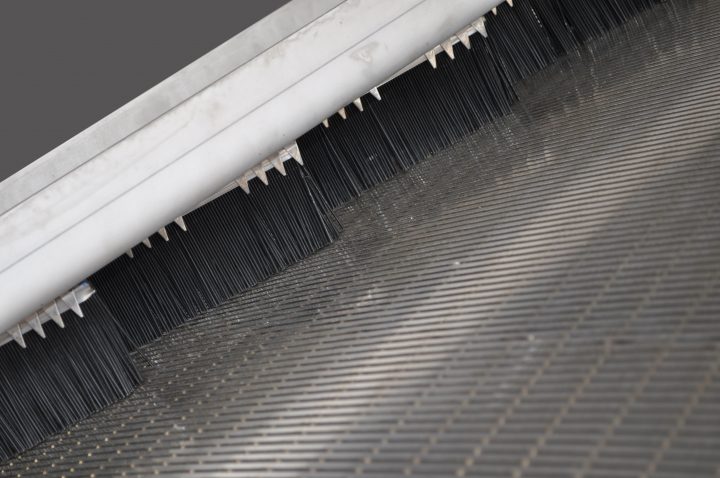

The best screens are also self cleaning, either by design, or with the addition of automatic brushes or jets of air or water that keep the screen clear of debris.

Some of the problems faced by unscreened intakes or intakes with the wrong technology installed: debris clogging a screen, fish blocking an in-line filter and fish on a syphon-irrigated plot.

HOW SCREENS WORK

Fisheries Scientist Tom Rayner explains what’s happening at the interface between fish and screens.

Australian fish species have limited swimming abilities compared to some species overseas. To protect them, we need water velocities under 0.1 metres per second.

Tom explains how modern screens achieve this and describes research looking at how screens help fish adults, juveniles, larvae and eggs.

He also outlines how this research is being collated to create guidelines for a new best practice around screen design, manufacturing and operations.

A PRACTICAL GUIDE

NSW DPI Fisheries has published a new practical guide and specifications for screen design and manufacturing.

These are based on the latest available science. They cover:

- screen materials

- water velocities

- surface area requirements

- orientation

- cleaning mechanisms

- fisheries specifications

- powered units

- inspection and maintenance

- safety and operation

Download the full guide and specifications.

SCREEN TYPES

A variety of different types of screens are available.

A range of screens are available in Australia. These can be adapted or combined to suit the needs of different water users and fish communities.

Factors like river conditions, diversion capacity and operation, local fish populations and site access all play a role in determining which type is best for a particular location.

CONE SCREENS

Best for shallow water and high debris situations, for either pumps or gravity-fed diversions.